After inspecting the damage to the Zero Gravity chair's frame, and since the warranty had run out, the customer and I had to determine if the cost of me repairing the chair would be lower than the price of a new chair.

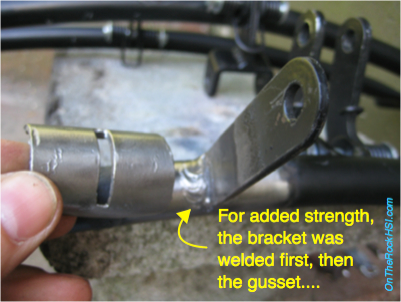

Now, cut a slot in the gusset for the bracket....

Then the weld itself had to be ground down to make room for the overlapping gusset.

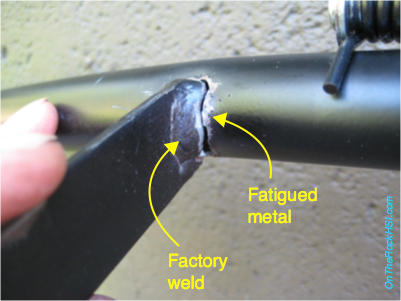

You can see that the actual weld itself did not fail. Rather, part of the steel tubing around the weld was ripped out. This is because the bracket's point of contact with the tubing was too small for the strength of the tubing. Even if the quality of the steel is inferior, that weakness could be overcome by lowering the force per square unit area, that is, by "spreading out" the point of contact that the bracket makes with the tubing frame. This can be accomplished with a reinforcing gusset fabricated from 3/4" black pipe stock.

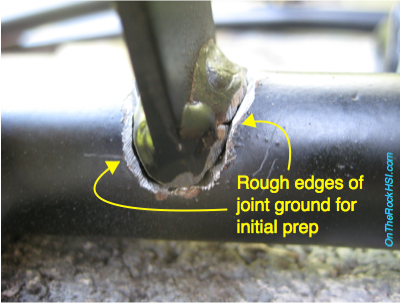

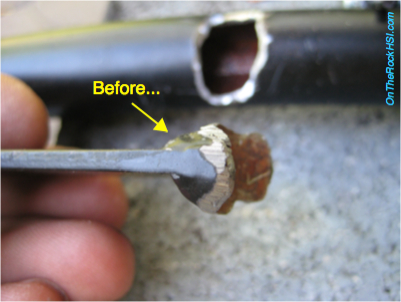

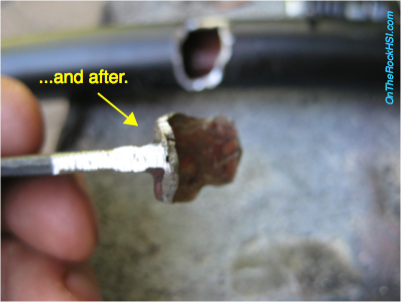

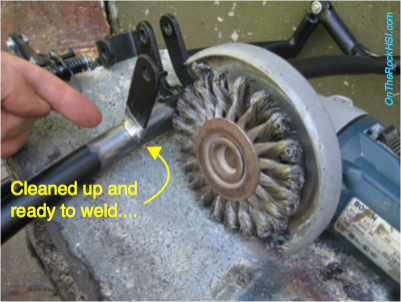

Of course, the edges of the hole and the old weld had to be cleaned.

Oh, yeah, that looks nice....

Next, use a wire wheel to make sure all surfaces are clean. Note that at this point, only the original bracket is being welded to the tubing. The gusset will be welded later.

Not too bad. However, some of this new weld had to be ground down to make room for the gusset.

Now, apply some paint to finish and protect it....

....and the other side.

Here's one side...

Oh, man, that feels good.

Good as new!

It ended up being significantly lower, so the repair went forward.